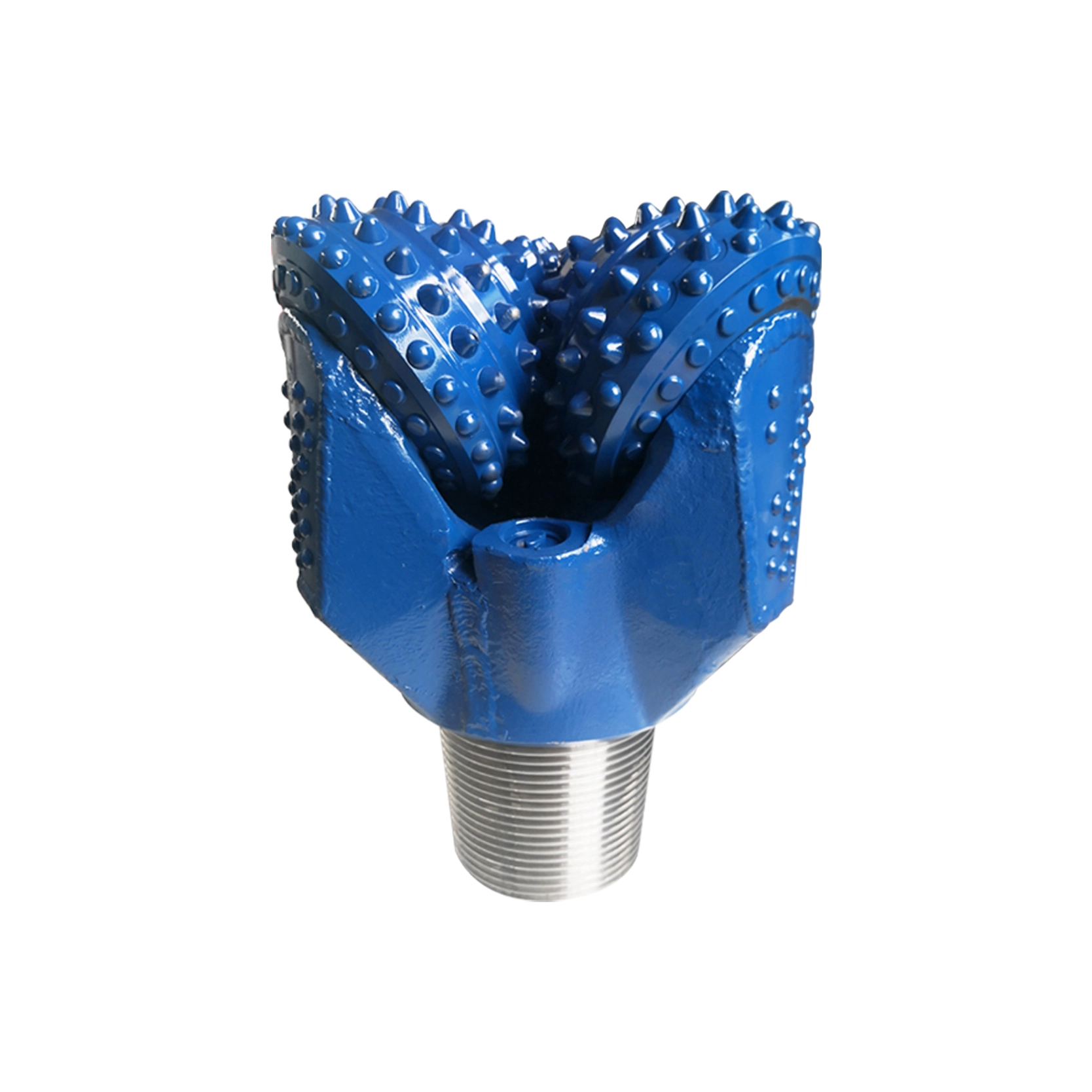

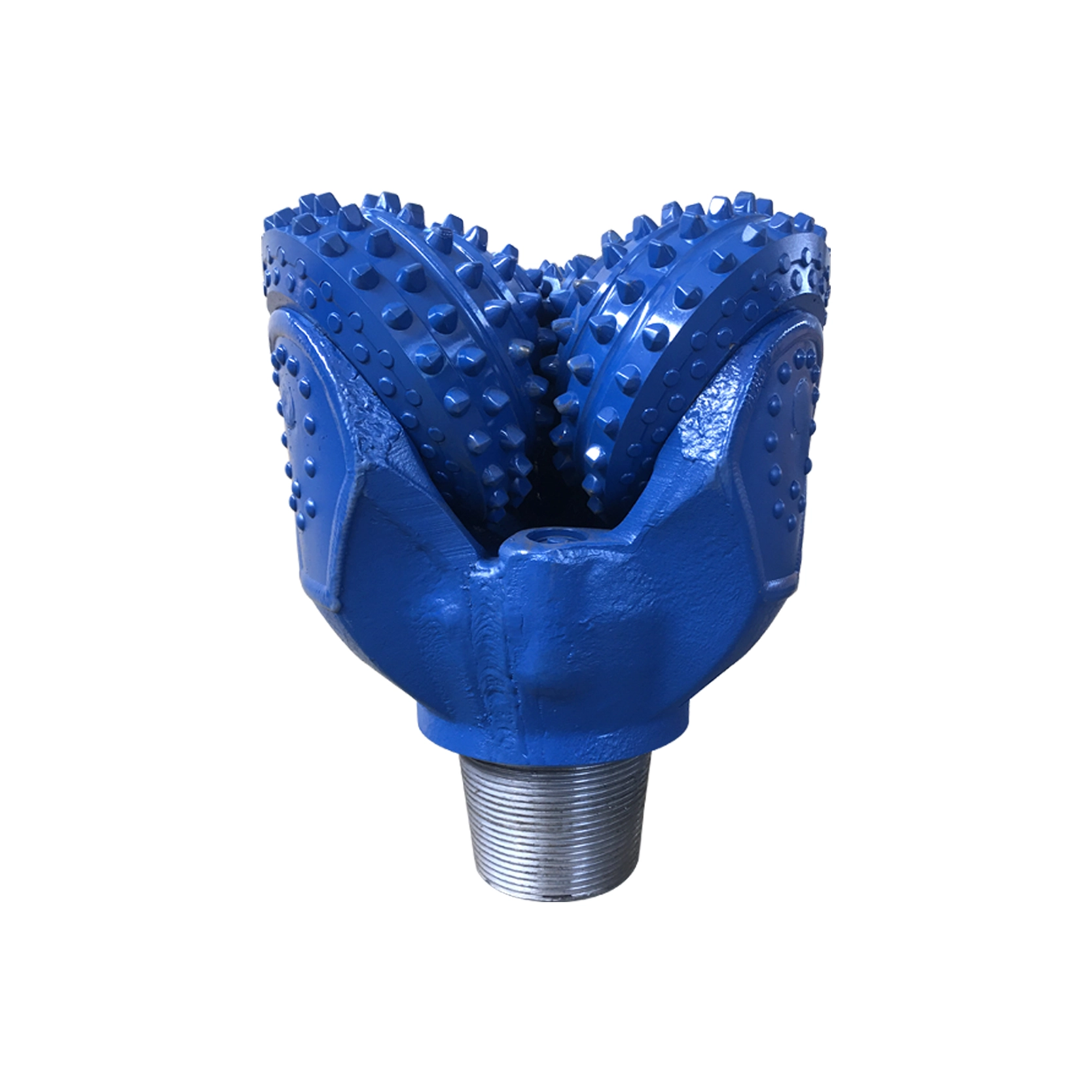

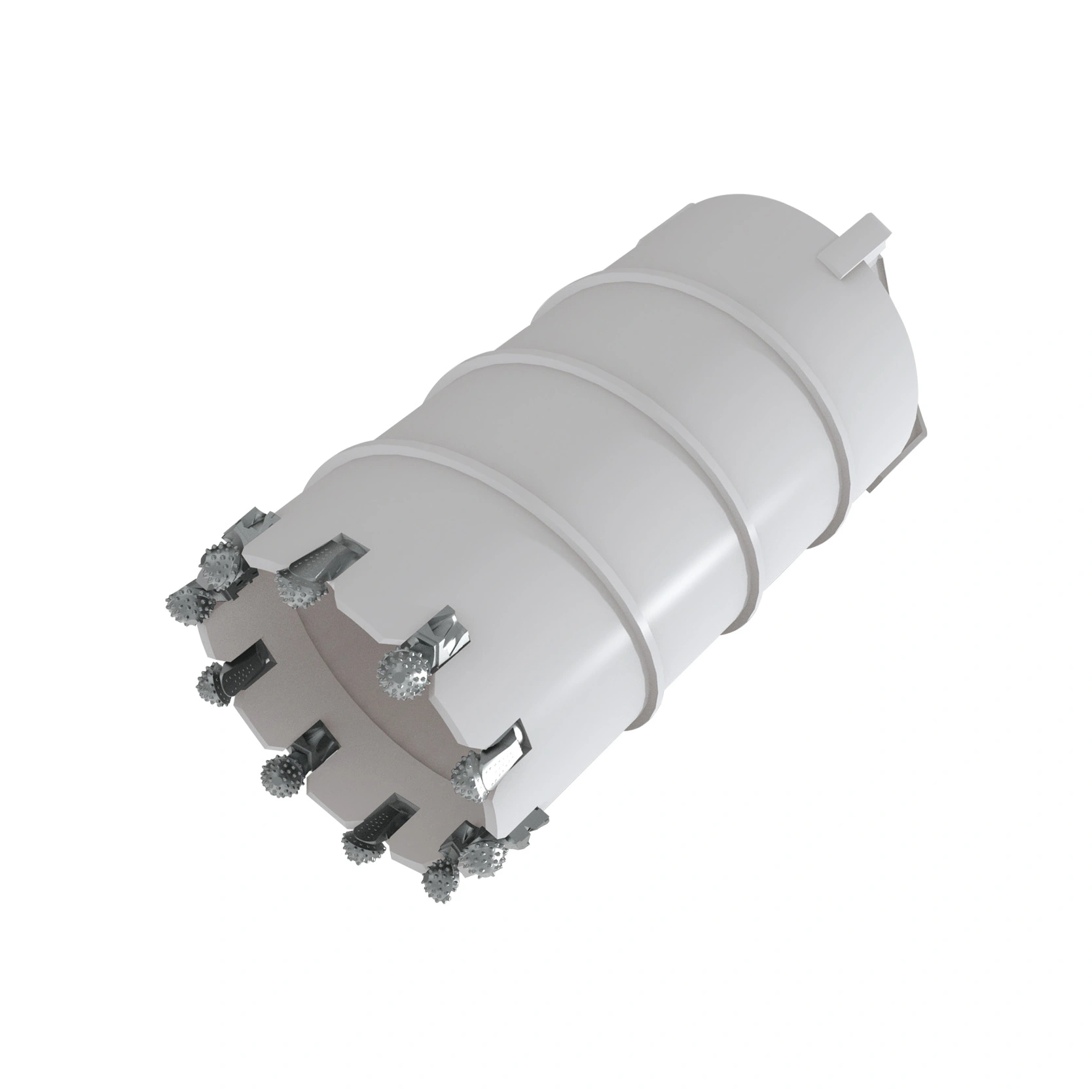

14 3/4" (374.6mm) IADC537 API TCI Tricone Rock Roller Bits For Well Drilling

keyword:

Classification:

Introduce

|

||||||||||||||

|

||||||||||||||

|

|||

| RPM(r/min) | 120-50 | ||

| WOB(KN) | 168-374 | ||

| Formations | Medium formations,such as medium shale, limestone, medium sandstone, medium formation with harder and abrasive interbeds,etc. | ||

Evaluate a tricone bits by below 5 main factors :

1. Cutting Structure

The teeth or inserts, mill tooth tricone bits must be hard-faced by tungsten carbide coating, the inserts must be high grade tungsten carbide.

The life of rock roller bits mainly depends on both teeth/inserts life and bearing life.

2. Gauge Structure

Optimized gauge protection design could keep the diameter fixed from top to bottom of hole to avoid shrinkage.

3. Bearing Structure

IADC537, the 3rd number 7 means journal sealed bearing with gauge protection on heel of cones.

4.Seal and Lubrication

Sealed bearing and lubrication of bearing is very important for life of rock roller bits, grease compensation system inside arms and cones lubricate bearing by a steady flow of high grade specific grease for rock roller bit only.

Regular Models

Applications

|

Related Catagories

|

|

|

|

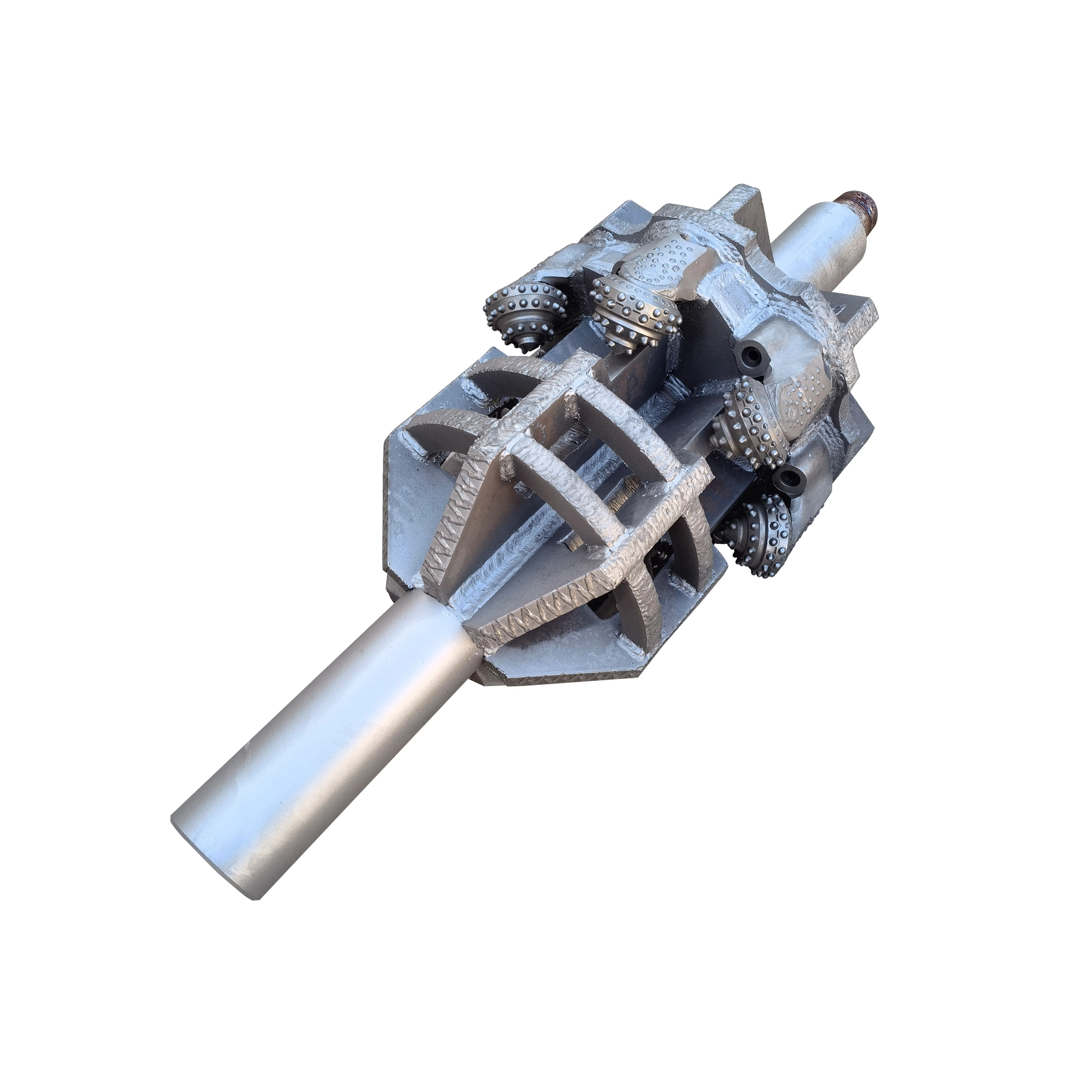

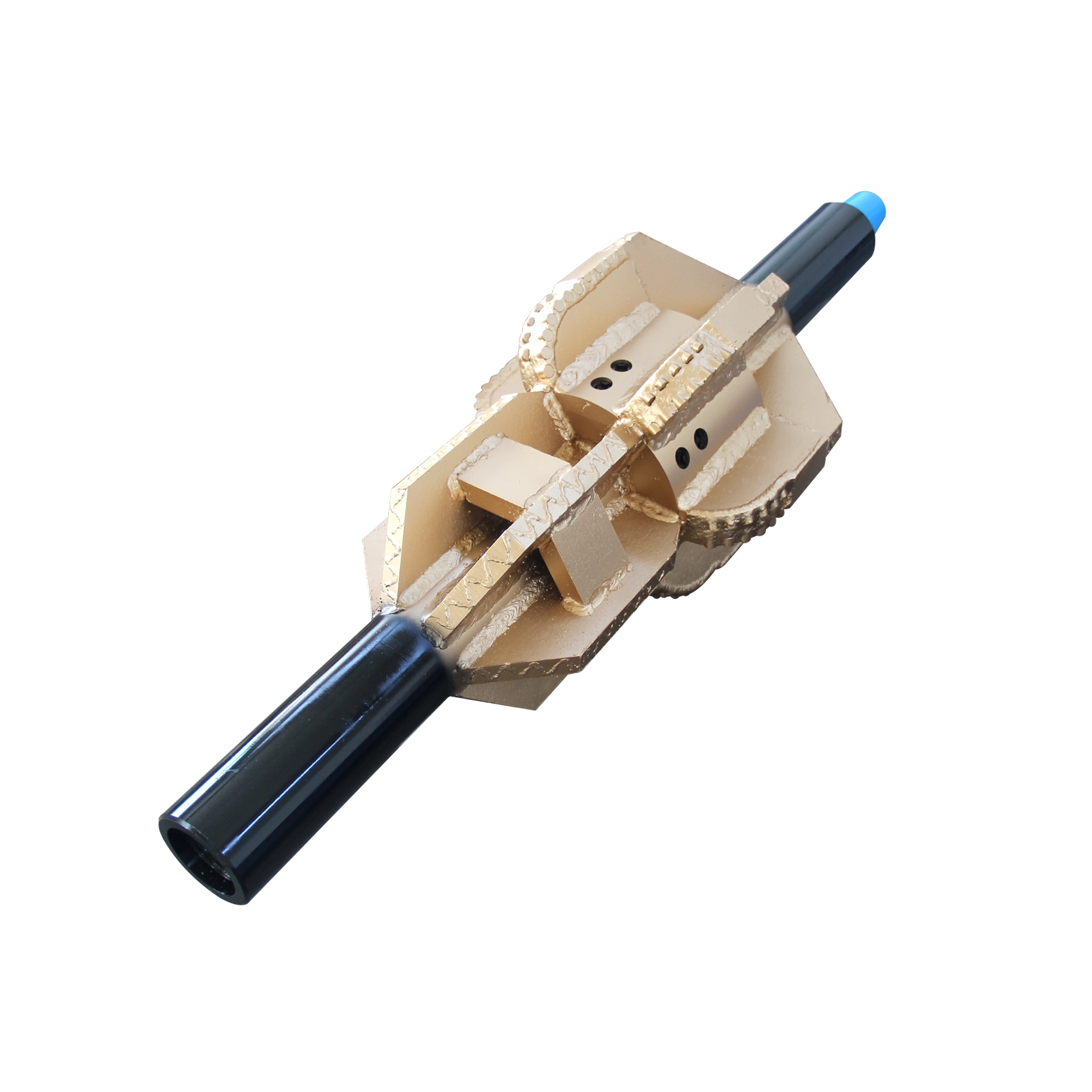

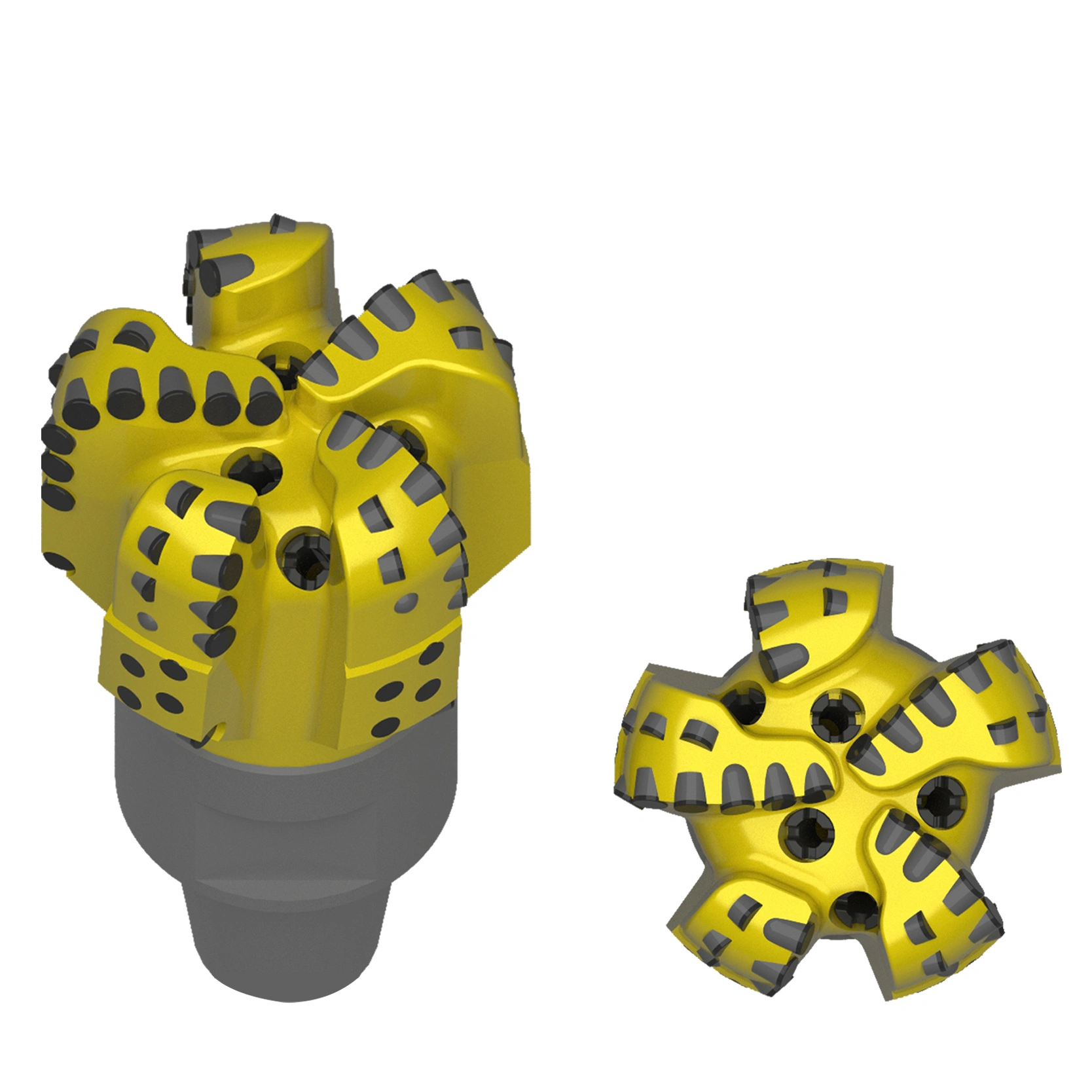

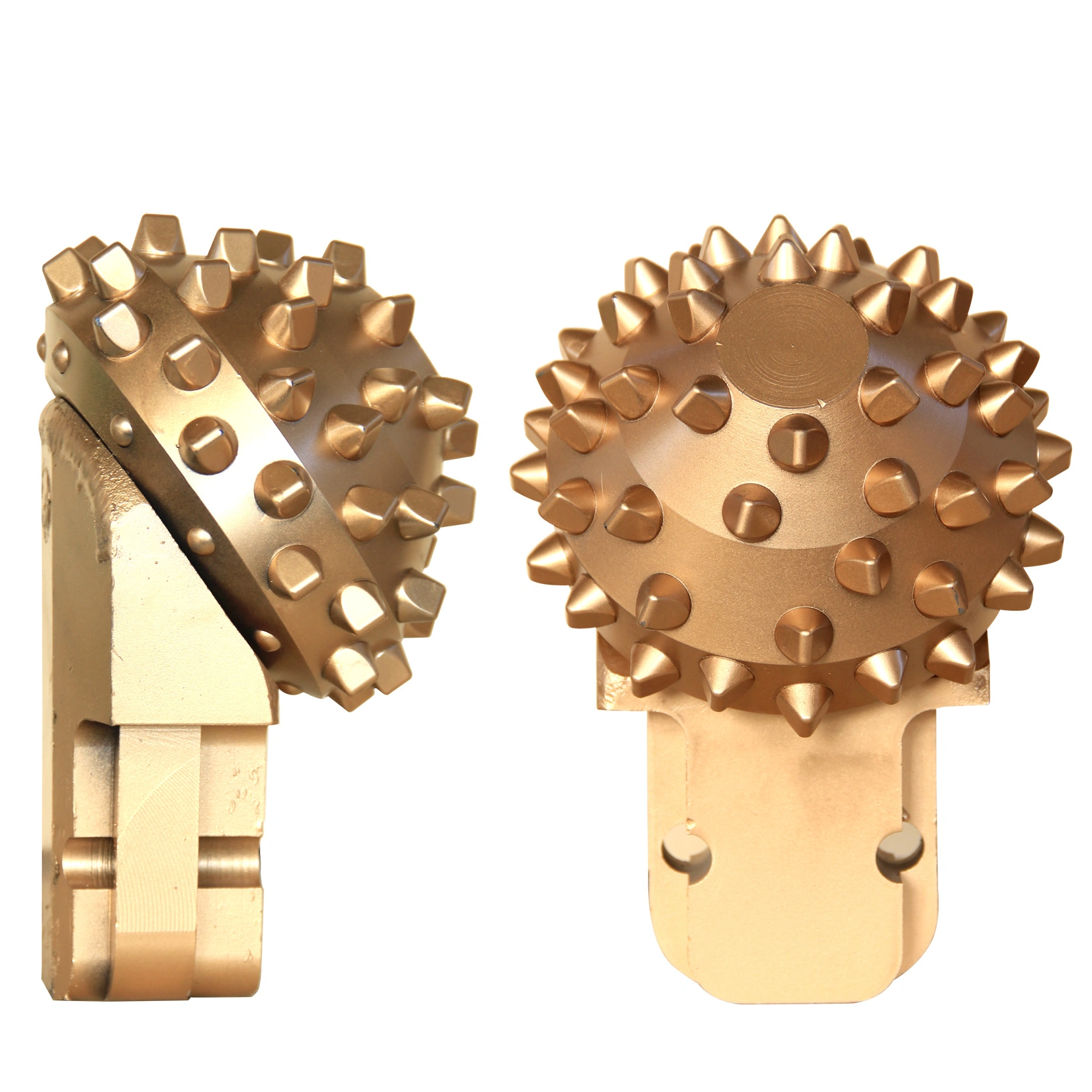

| PDC Bits | Hole Opener | Roller Cones (Thirds) | Piling Roller Cones |

Inquiry Now

Welcome to know our products

Get more product service information

CNTACT US

No.319-324, F1, Shoulashou Int'l. Autoparts Center,Shijing Road,Hejian City, Hebei Province, China

Message