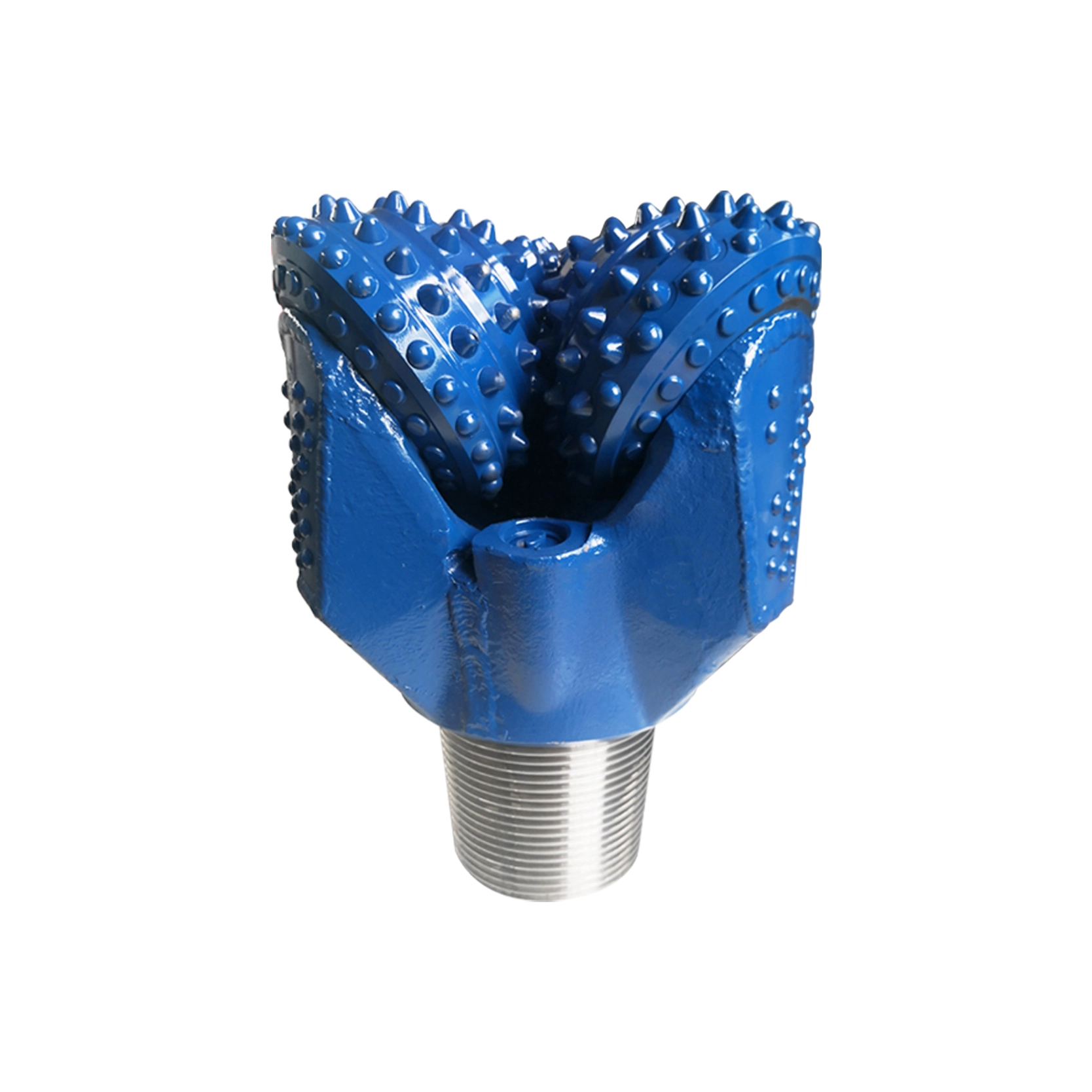

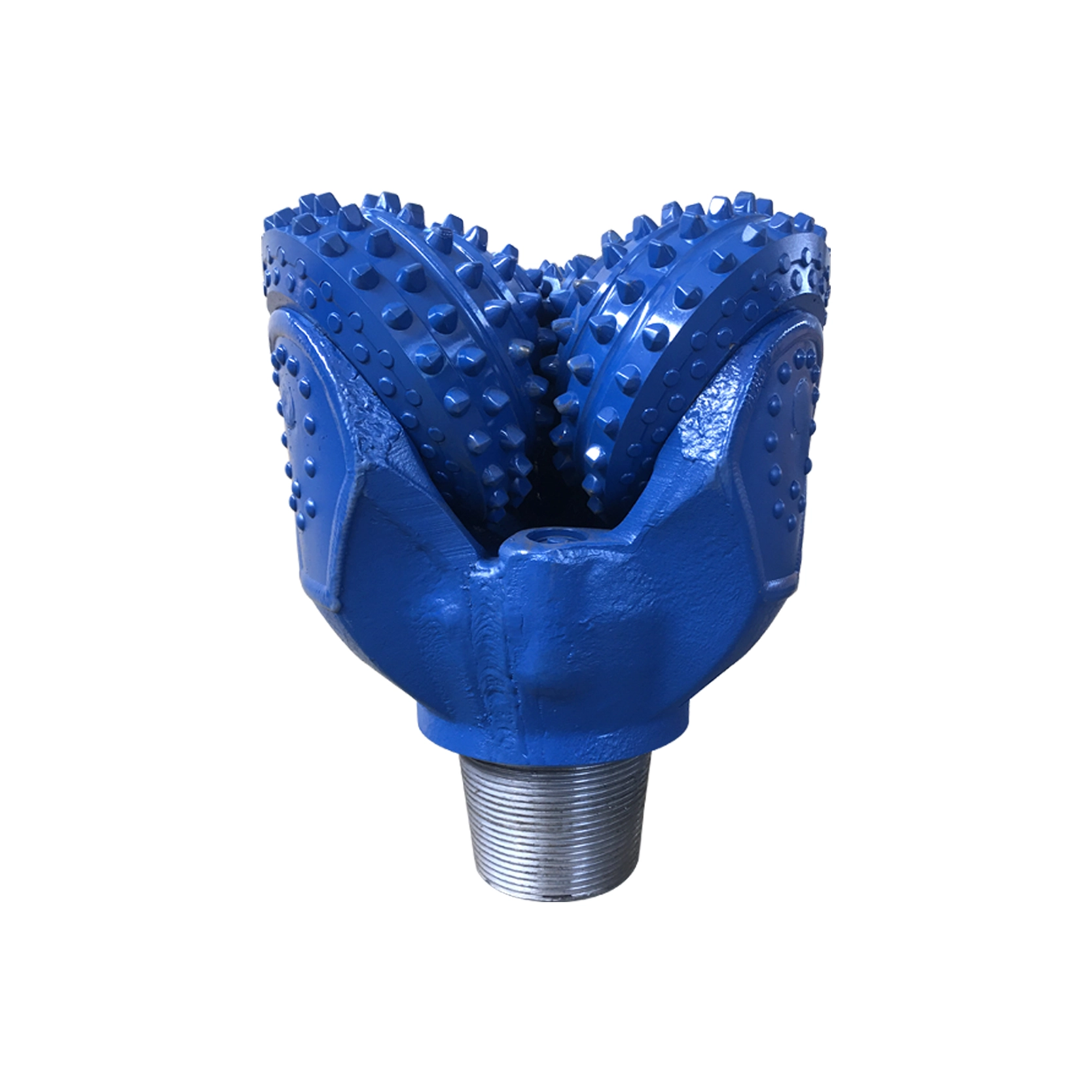

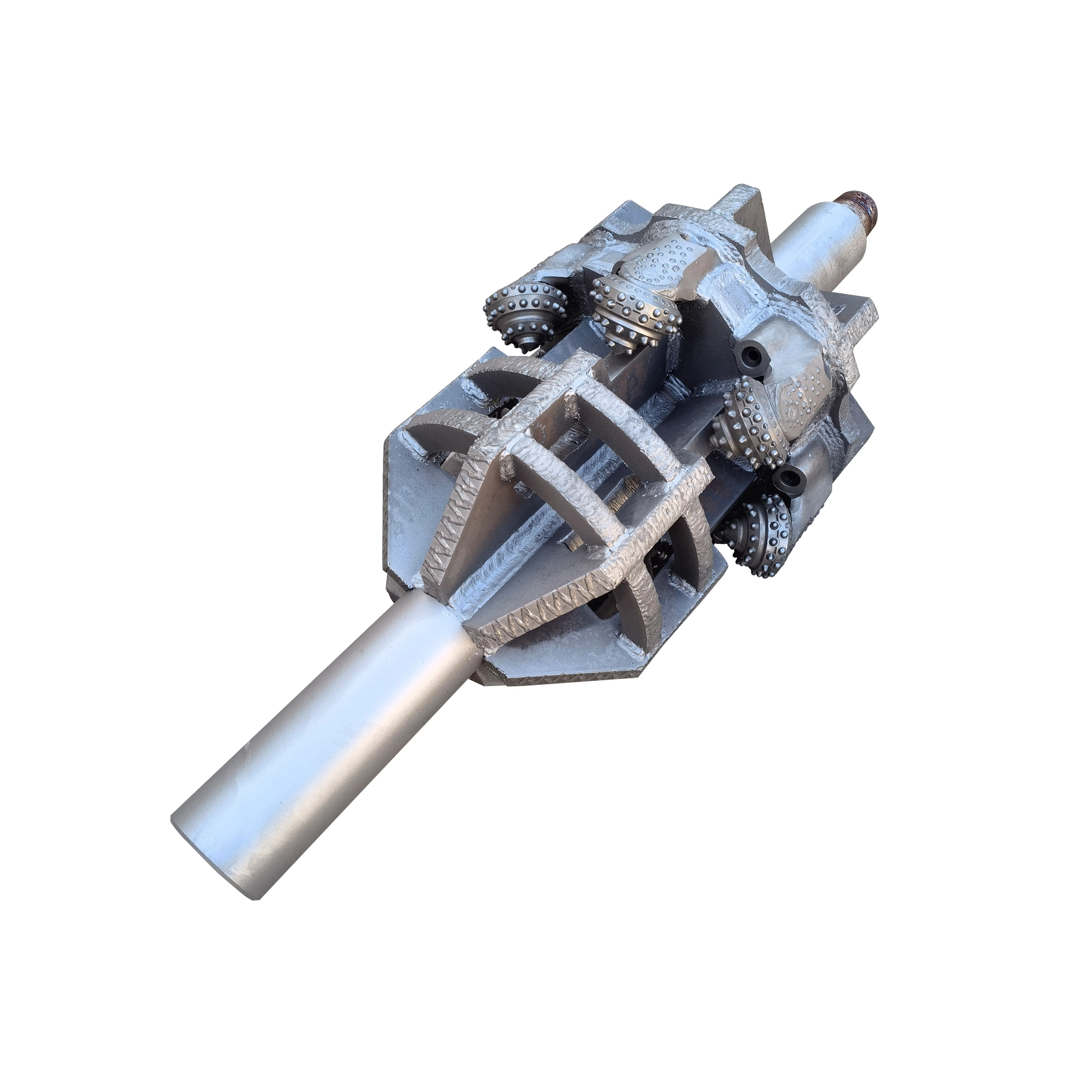

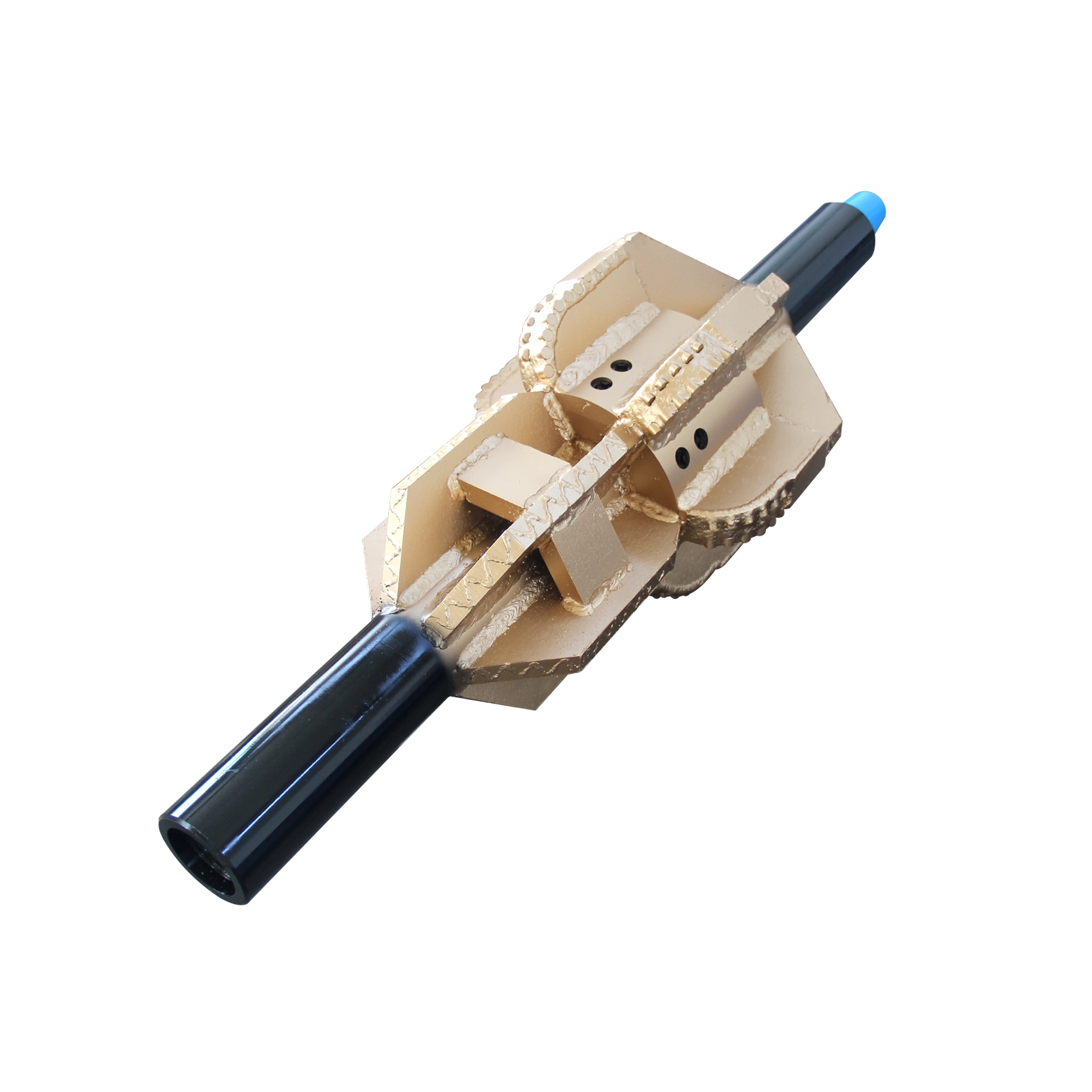

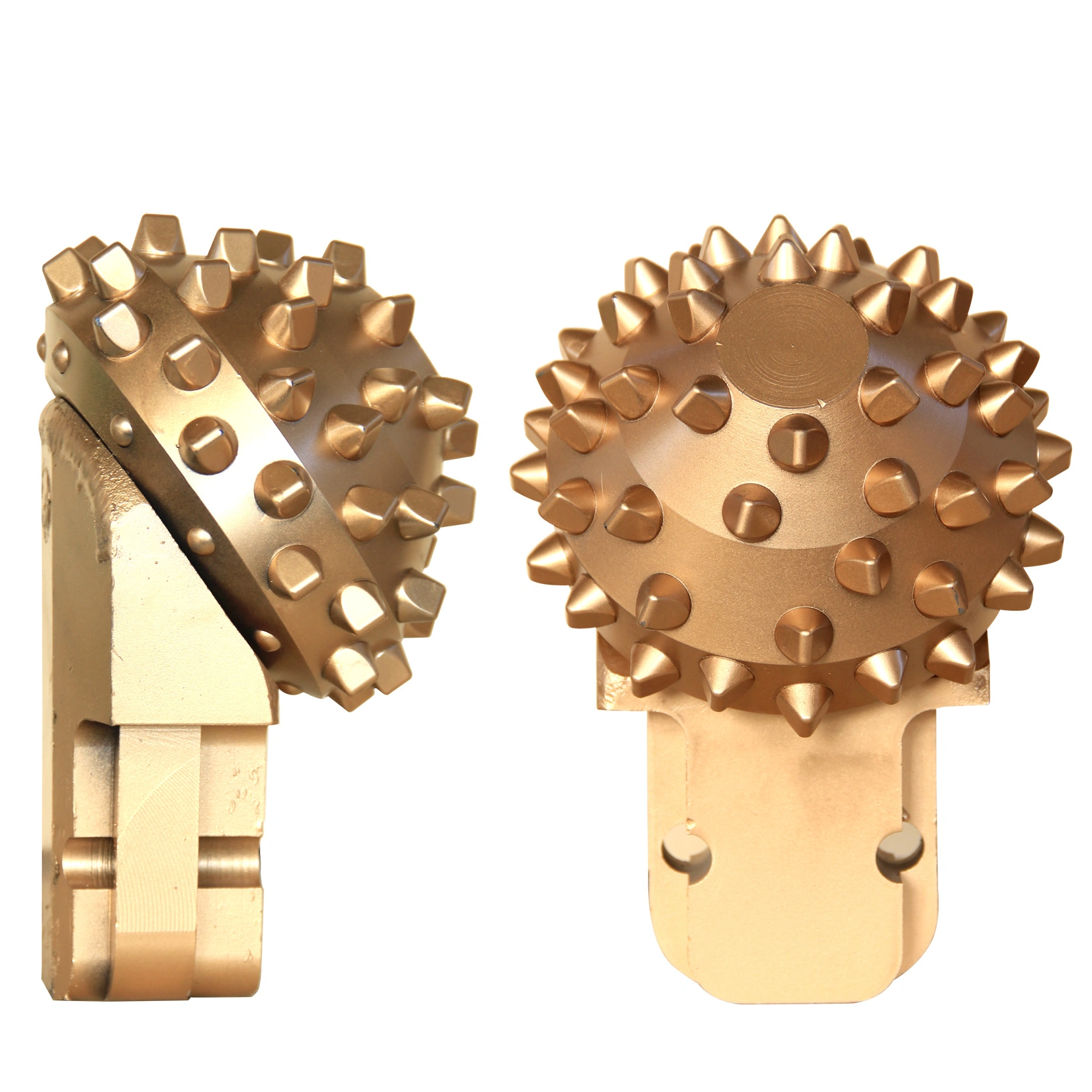

Hard Rock Core Barrel Roller Cone Bits NG2(56/9)

keyword:

Classification:

Introduce

Technical specification of roller cone bit NG2(56/9)

| Raw Material | |||||||||||

| Cone | 15MnNi4Mo | ||||||||||

| Arm | 15CrNiMo | ||||||||||

| Tooth | Tungsten Carbide Inserts | ||||||||||

| Tooth Type | |||||||||||

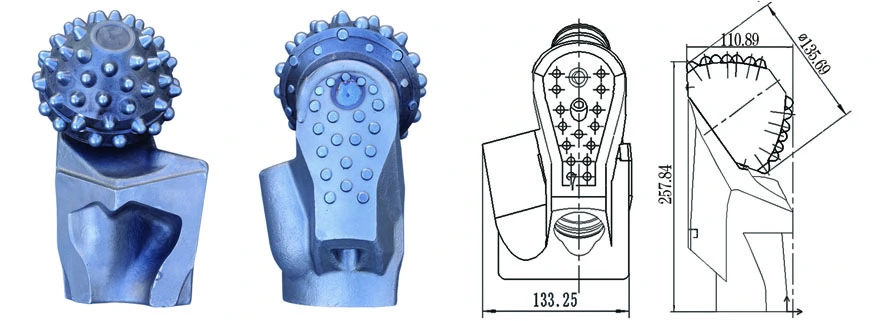

| Tooth Qty.&Diameter | 56 PCS / 14mm | ||||||||||

| Tooth Height | Total height: 20.3mm, inside height: 11.3mm, outside height: 9mm | ||||||||||

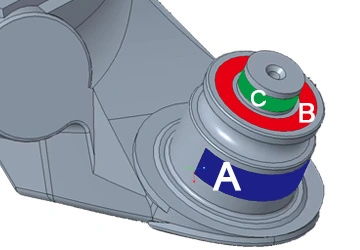

| Bearing and Lubrication | |||||||||||

| Tungsten carbide enhanced on bearing |

|

||||||||||

| Grease Lubrication & Bearing Seal |

|

||||||||||

1>NG2 has two types, one is 49 pcs of carbide teeth(outside height of teeth is 7.7mm), another is 56 pcs of carbide teeth(outside height of teeth is 9mm).

NG2-49/7.7 has better performance in drilling extremely hard rocks, NG2-56/9 has higher penetration rate in medium hard and hard rocks.

2>Steel material of arm and cone is important for the quality, we use 15MnNi4Mo steel for cone, and we use 15CrNiMo steel for arm, it is standard steel material for oil well drilling tricone bit.

3>The bearing is sealed, grease is injected by vacuum machine.

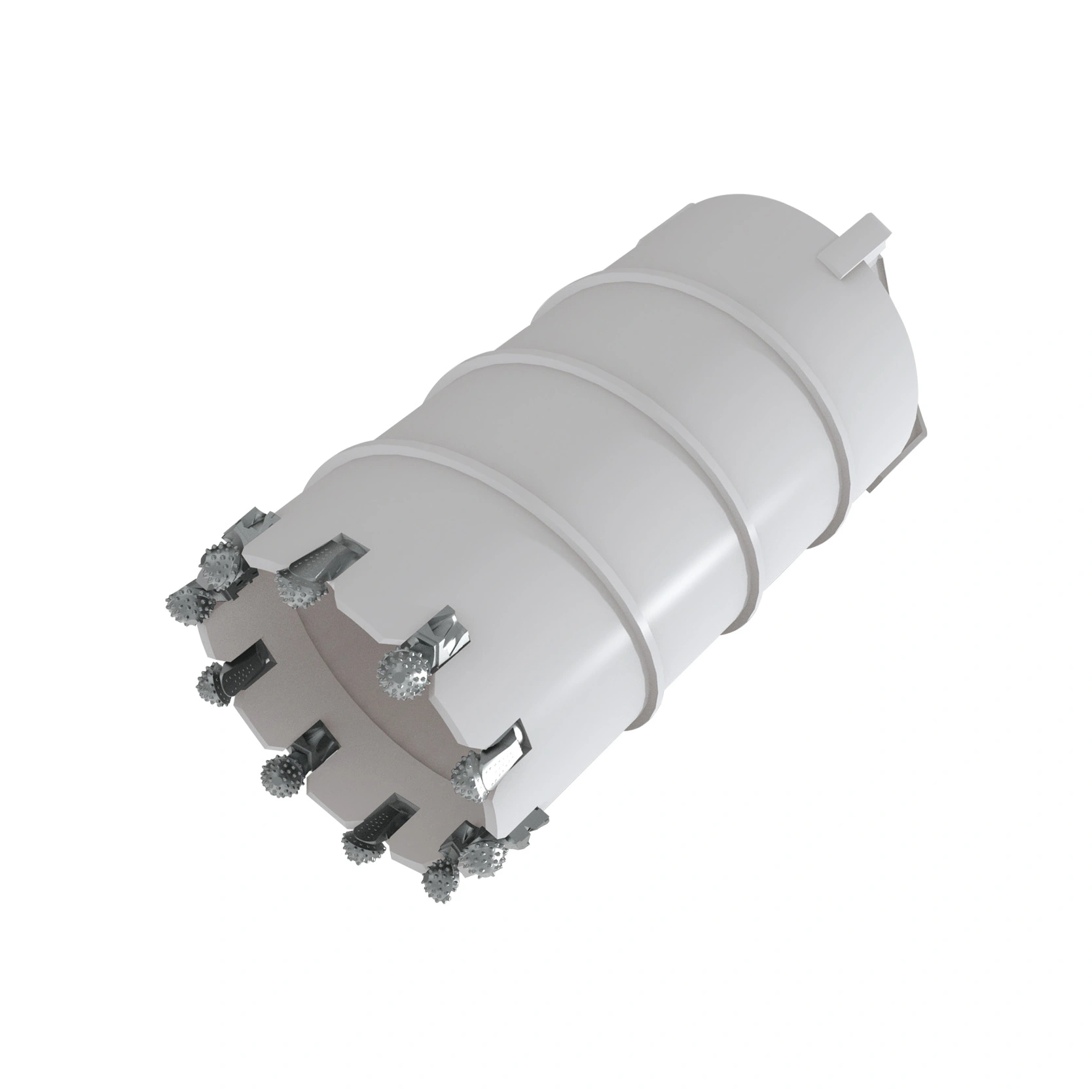

Regular Models

Applications

|

Related Catagories

|

|

|

|

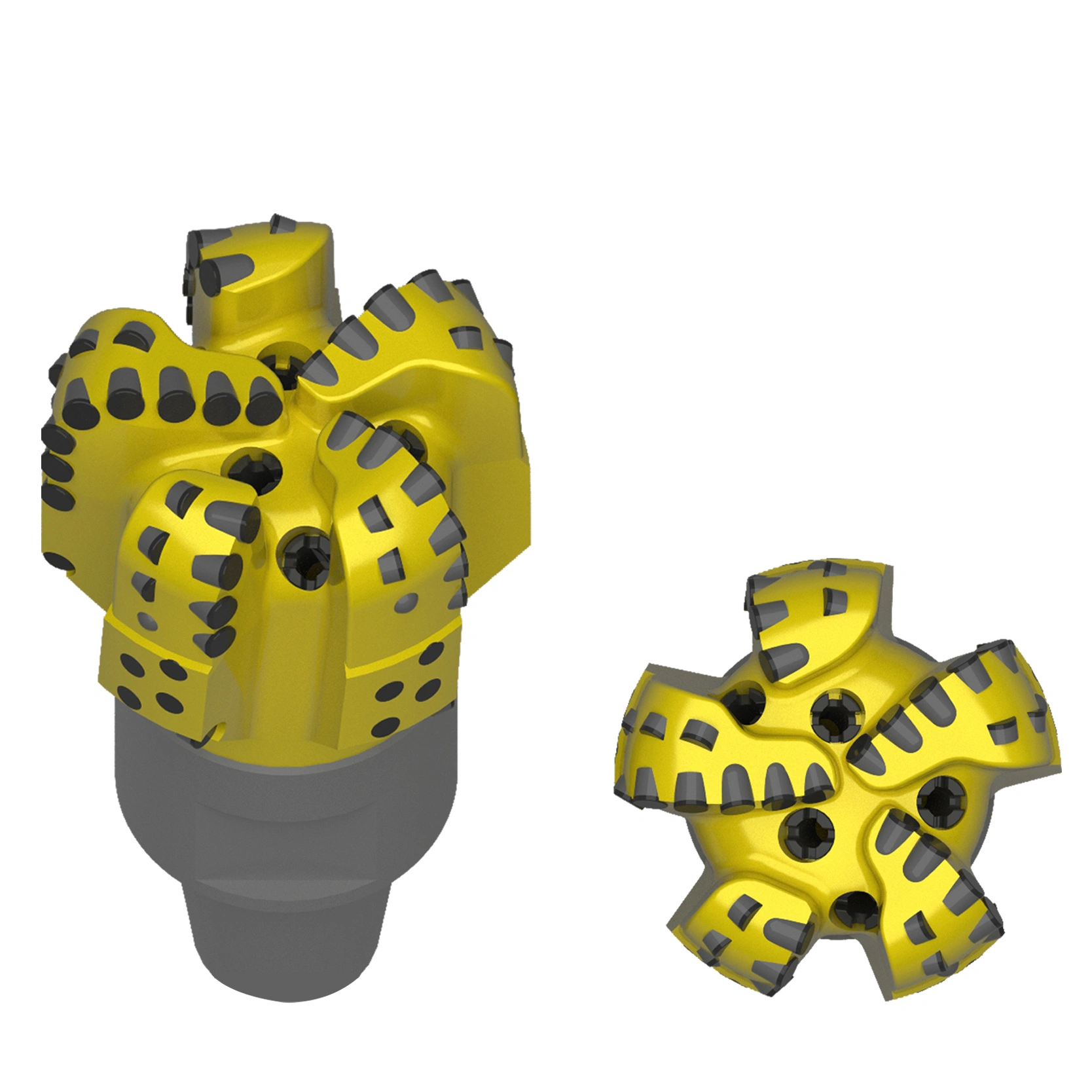

| PDC Bits | Hole Opener | Roller Cones (Thirds) | Piling Roller Cones |

Previous Page

Inquiry Now

Welcome to know our products

Get more product service information

CNTACT US

No.319-324, F1, Shoulashou Int'l. Autoparts Center,Shijing Road,Hejian City, Hebei Province, China

Message